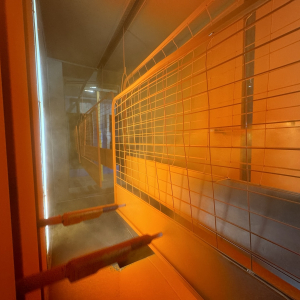

Steel Props - Before & After

By refurbishing and re-using steel products, together we significantly reduce the demand for new raw materials, helping to conserve natural resources and lower carbon footprints.

Refurbishing steel products prevents them from ending up in landfills, reducing environmental pollution and promoting a cleaner, greener planet.

By refurbishing and re-using steel products, together we can significantly reduce the demand for new raw materials, helping to conserve natural resources and lower carbon footprints.

Our services are an integral part of the circular economy, focusing on extending the lifecycle of steel products through repair and refurbishment, to minimise waste and maximises resource efficiency. Partnering with us supports green initiatives and CSR programmes, showcasing your commitment to environmental stewardship and sustainability.

The combination of zinc electroplating and powder coating offers exceptional corrosion resistance, ideal for products exposed to harsh environments or demanding applications. Rigorous quality control measures are in place at every stage of the process to ensure that each product meets the highest standards of quality and performance

Ready to Start Your Project?

Please fill in the form below and we will get back to you.

No project is too big or small.

BENEFITS

- Poor or damaged surface finishes are removed and new, often better than OEM finishes are applied.

- Worn or damaged components are restored or replaced with new - to the latest specification.

- We can also provide you with detailed reports on the environmental benefits of our refurbishment processes, including metrics on waste reduction, energy savings, and carbon footprint reduction, allowing you to track and showcase your sustainability efforts

- Not only are there significant savings compared to the cost of new replacement equipment, the process is environmentally sound.

- Co2 emissions are often as low as one tenth of those emitted in the manufacture of new equipment.

All this is backed up by competitive pricing offering great value for your investment.

Our central UK site in Kirkby-in-Ashfield Nottinghamshire is just 5 minutes away from the M1.

"Our refurbished trolleys and shelves look brand new, I have to say, the process was smooth and the results fantastic. Our customers have noticed the difference too"

Garden Centre Trolleys

OUR SERVICES

EDGE PROTECTION BARRIERS

NZG refurbishes edge protection barriers using zinc electroplating and powder coating, delivering finishes that last up to twice as long as standard coatings while reducing costs by 26–55%. Fully EN 13374 compliant with fast UK-wide turnaround.

LEARN MORE

ZINC ELECTROPLATING

Exceptional corrosion resistance, ensures your metal components stay protected against the elements. Consistent and reliable quality, backed by years of experience.

LEARN MORE

Committed to Sustainable Practices

Our company is committed to sustainable practices, using eco-friendly materials and processes that minimise environmental impact. We are regulated by the Environment Agency and Severn Trent Water Authority so you can be sure your products are finished by using the most ecofriendly process.

NZG partner with McDermot to offer a great sustainable alternative to Galvanizing. By using the most environmentally friendly chemicals possible, NZG process of Zinc electroplating produces a thinner and more uniform layer of zinc compared to galvanizing whilst reducing the impact on the environment.

FAQS

Yes, refurbishing metal is typically 30–60% more cost-effective than manufacturing or buying new components. At NZG, our refurbishment process restores full performance and extends asset lifespan, offering a sustainable and budget-friendly alternative to replacement.

In most cases, yes. Rusted or corroded steel can often be restored unless structural integrity is severely compromised. At NZG, corrosion is removed through surface preparation before applying zinc electroplating and powder coating. This process restores appearance and corrosion resistance to near-new condition.

Refurbished steel can last just as long as new steel when treated correctly. With NZG’s combined zinc-electroplating and powder-coating system, refurbished components typically achieve 10–20 years of service life, depending on environmental exposure and maintenance.

Steel refurbishment plays a key role in achieving net-zero and circular-economy targets by reducing demand for new steel production, which is energy- and carbon-intensive. At NZG, our refurbishment methods cut carbon emissions, energy use, and waste, supporting UK sustainability standards.

Yes, refurbished steel that meets testing and certification requirements is fully suitable for public infrastructure and construction projects. At NZG, all refurbished components comply with relevant BS and EN standards, ensuring safe, sustainable, and regulation-compliant performance.

SUPPLIERS TO